In the realm of operational excellence, efficiency is key. Organizations worldwide are continually seeking methodologies to optimize workflows, reduce waste, and enhance productivity. One such methodology that has gained widespread acclaim is the 5S approach. At Wiselearner IT Service, we're dedicated to equipping professionals with the knowledge and tools they need to implement and leverage the power of the 5S Methodology effectively.

What Does 5S Stand For?

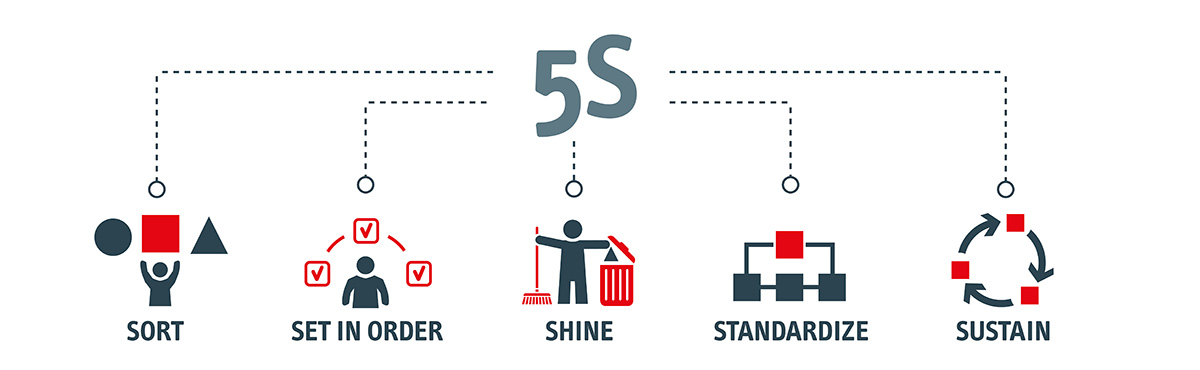

The 5S Methodology derives its name from five Japanese words, each beginning with the letter "S," representing the fundamental principles of workplace organization and optimization:

Seiri (Sort): The first step involves sorting through items in the workspace, separating the essential from the non-essential. By eliminating unnecessary items, clutter is reduced, and efficiency is enhanced.

Seiton (Set in Order): Once unnecessary items are removed, the next step is to organize the remaining items systematically. Tools, equipment, and materials are arranged in a logical and efficient manner, minimizing search time and maximizing accessibility.

Seiso (Shine): A clean and orderly workspace is essential for productivity and safety. The "Shine" step involves regular cleaning and maintenance to ensure that the workspace remains free of dirt, debris, and hazards.

Seiketsu (Standardize): Consistency is key to sustaining improvements over time. Standardizing processes, procedures, and visual cues ensures that everyone adheres to the same high standards, fostering a culture of excellence and continuous improvement.

Shitsuke (Sustain): The final step focuses on maintaining the gains achieved through the previous steps. By fostering a culture of discipline, accountability, and ongoing training, organizations can ensure that 5S practices become ingrained in the company culture and endure long-term.

Tools for 5S

Implementing the 5S Methodology requires the right tools and resources to support each step of the process. At Wiselearner IT Service, we provide comprehensive training on a range of tools and techniques tailored to the unique needs of each organization, including:

Visual Management Tools: Visual cues such as color-coded labels, floor markings, and signage help communicate standards and facilitate quick identification of tools, materials, and workstations.

5S Red Tags: Red tags are used during the sorting phase to identify items that are not immediately necessary. They serve as a visual indicator for decision-making and help prevent unnecessary clutter.

Checklists and Standard Operating Procedures (SOPs): Clear documentation of procedures and standards ensures consistency and helps guide employees through each step of the 5S process.

Kaizen Events: Kaizen, or continuous improvement events, provide opportunities for teams to collaborate, identify inefficiencies, and implement solutions in real-time, driving rapid improvements across the organization.

Conclusion

In today's competitive landscape, organizations must continually strive for excellence in efficiency and productivity. The 5S Methodology offers a proven framework for achieving these goals, fostering a culture of organization, cleanliness, and continuous improvement. At Wiselearner IT Service, we're committed to empowering organizations with the knowledge and tools they need to implement 5S effectively and drive lasting success. Join us on the journey to operational excellence and unlock the full potential of your workforce with the 5S Methodology.